Developing a cost-effective and environmentally sound recycling process for lithium-ion batteries requires a suite of complex techniques rooted in fundamental chemistry and materials science.

It requires advances in separation techniques, a deep understanding of evolving battery chemistries and geometries, and the development of novel electrochemical techniques for relithiation.

It is a difficult challenge.

Unlike lead-acid batteries, which contain only three materials that require a few simple operations, lithium-ion batteries have several materials with complex designs. The methods to separate them are either expensive, energy intensive, or simply don’t exist. The chemistries and morphologies of these compound materials are complex and customized by individual manufactures, making a standard recycling method nearly impossible. What material is recovered, often is not recovered completely or has impurities that reduce its performance.

In addition, the process of recovery often costs more than the material is worth. Battery owners must pay recycling operators to cover the cost of recycling batteries with low-cobalt content. This problem will only increase as cobalt-rich battery systems are phased out, leaving one less recycled component for sale.

Developing an efficient recycling process that recovers material in high-value form for sale back to manufacturers is key to encouraging lithium-ion battery recycling.

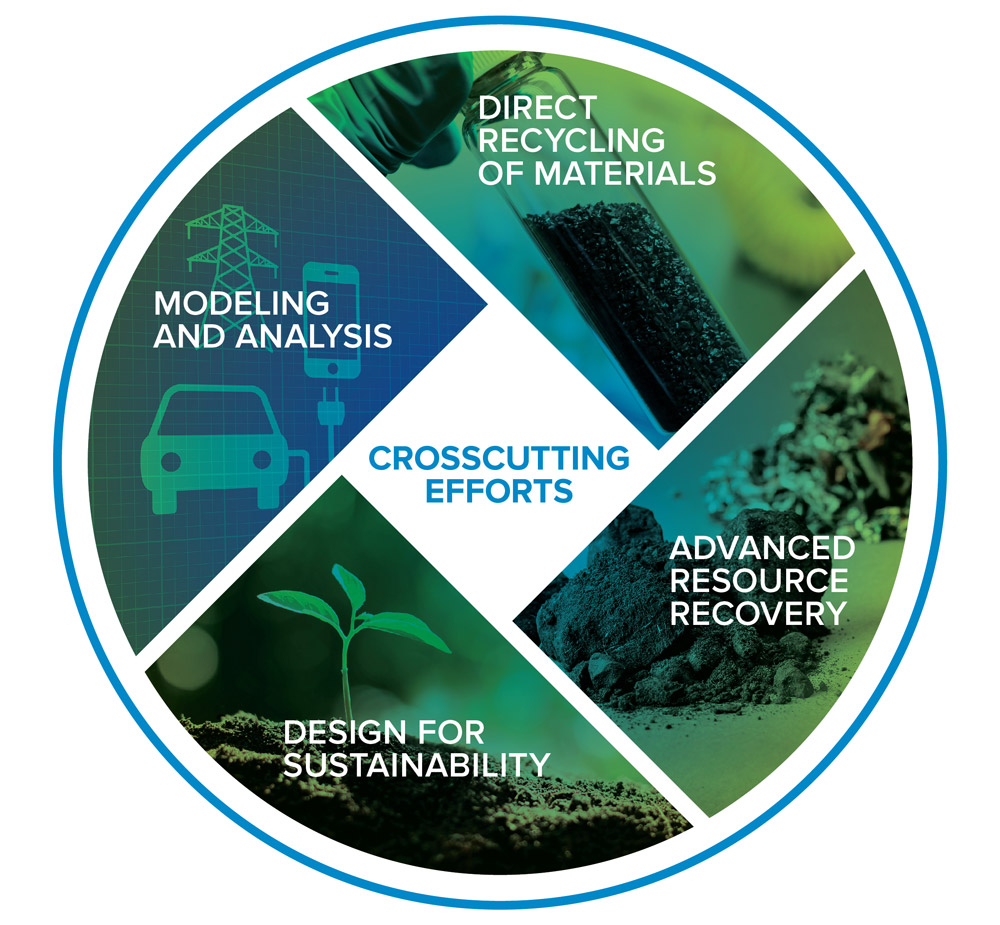

To do that, the Advanced Battery Recycling R&D Facility team has focused on solving four of the largest R&D challenges to wide spread adoption: