This focus area takes advantage of well-established DOE facilities for materials production, cell building, cell testing and diagnostics. ReCell collaborators utilize these cross-cutting capabilities to accelerate deployment of R&D results from individual tasks to industry.

ReCell has four key crosscutting efforts:

Cell Analysis, Modeling and Prototyping (CAMP) Facility

The CAMP Facility actively supports the efforts of the ReCell Center by providing baseline materials, fabricating trial electrodes and baseline electrodes, fabricating and testing coin cells, and fabricating and testing of pouch cells. It has established a thorough test matrix and protocols to evaluate electrochemical performance of active materials of interest.

Post Test Facility

Post-test diagnostics of aged batteries can provide additional information regarding the cause of performance degradation, which previously could be only inferred. The facility combines microscopy, spectroscopy, and chromatography in a controlled-atmosphere glove box to characterize materials without air exposure. These results will help us identify issues in the recycled materials, such as effectiveness of different recycling processes in separating initial mixtures of cathode, anode, supporting foils, and casing materials.

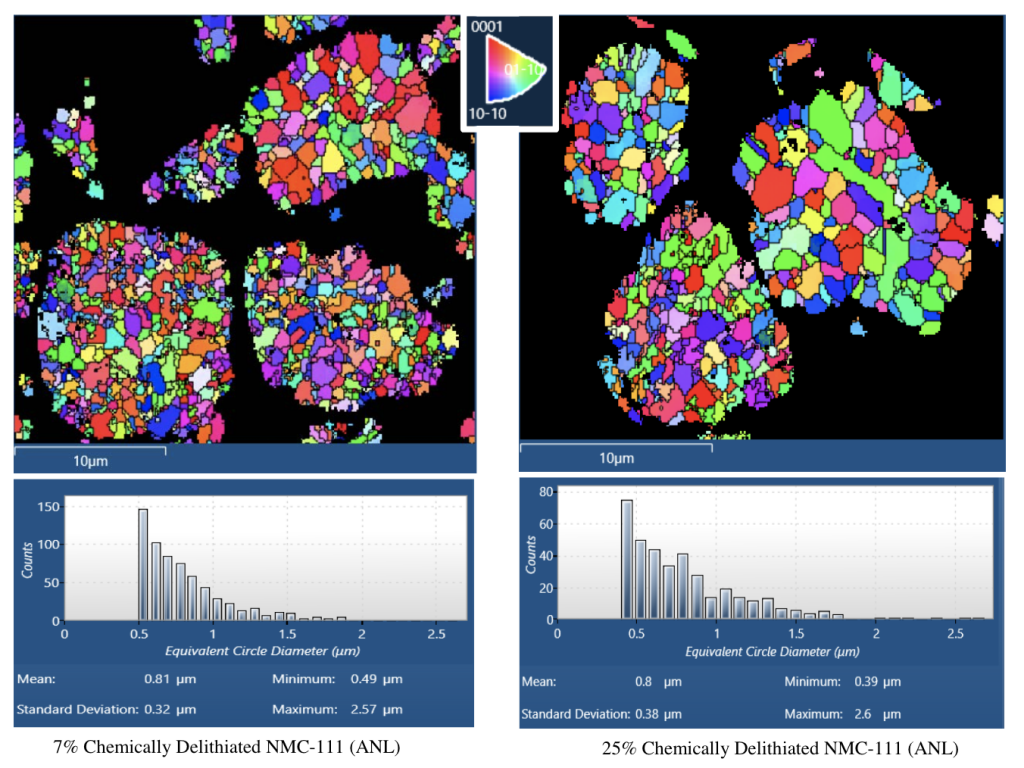

Diagnostics of Aged Materials (EBSD)

This capability aims to provide statistical distributions of structural change, composition, and morphology of aged electrode materials using electron backscatter diffraction (EBSD), which enables analysis of cathode materials at the primary particle level.

Materials Engineering Research Facility (MERF)

The MERF houses a wide variety of equipment for process R&D and validation of emerging manufacturing technologies. The MERF supports ReCell by providing interaction and collaboration with staff scientists who have extensive process knowledge and equipment for scaling technologies developed within the Center. The goal of the ReCell Center is to develop technologies that can be directly transferred to industry. The scale-up process is not straightforward, thus advancing our laboratory-scale processes beyond the bench includes identifying viable processes, eliminating or decreasing toxic chemical useage, reducing the amount of waste generated, and modeling processes to determine what the environmental impacts are and ensure processes are economically viable.

Learn more about the individual projects in these areas in our Quarterly Reports and Publications.

Focus Area Lead: Matt Keyser (National Renewable Energy Lab)