Developing tools to provide a deep materials/process understanding and evaluate economic and environmental impacts.

The main goal of ReCell is to develop lithium-ion battery recycling technologies that will be used by industry in the United States. In order for our processes to be adopted by industry, they must be economical and environmentally sound. Work in ReCell’s Modeling and Analysis focus area includes screening successful laboratory projects to determine if they can make it in the real world while ensuring that we have a thorough understanding of the recycled materials we generate and the markets and supply chains they will be captured in.

The Modeling and Analysis focus area includes a few major efforts to help direct laboratory research towards viable processes:

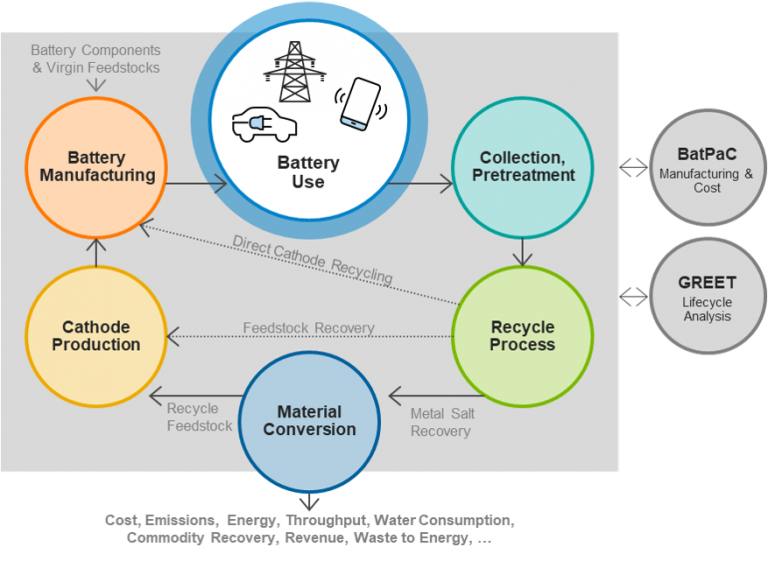

- Environmental and Economic Modeling: The EverBatt model is an Excel-based tool that evaluates costs, energy use, and environmental impacts of every step of an EV battery’s lifecycle (except for the use phase). It can be used to compare production from virgin raw materials with recycling by different methods at different scales, or to simply compare two different ways of doing a single step in the battery supply chain. The model uses inputs from two well-respected Argonne models, GREET and BatPaC. The costs and environmental impacts of the different processes can be used to inform R&D and down-select which processes will be scaled up for later phases of the ReCell work.

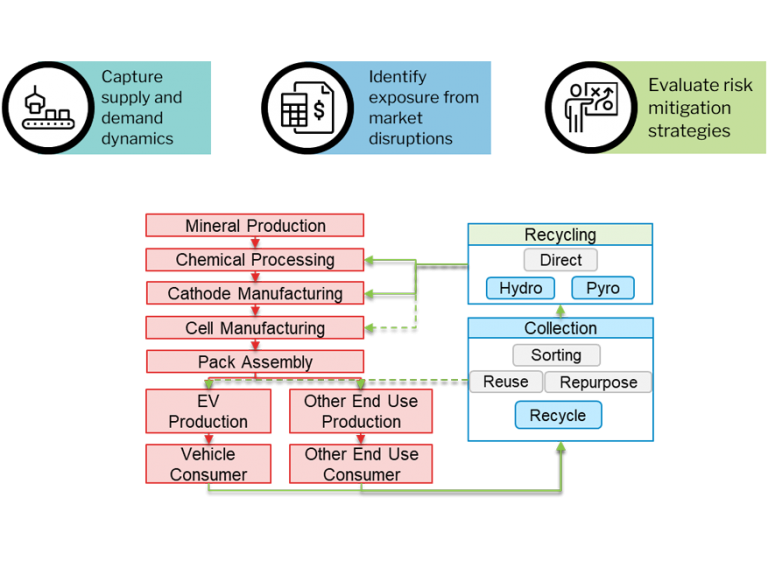

- Dynamic Market Modeling: GCMat-Bat (Global Critical Materials) is an agent-based model (ABM) of the lithium-ion battery supply chain from mineral production through end-of-life recycling. GCMat-Bat simulates dynamic economic markets, including decision-making behaviors, capturing complex supply, demand, and business dynamics, as well as interactions and learning of supply chain agents. With this capability, efforts to strengthen the resilience and competitiveness of global and domestic lithium-ion battery supply chains can be evaluated.

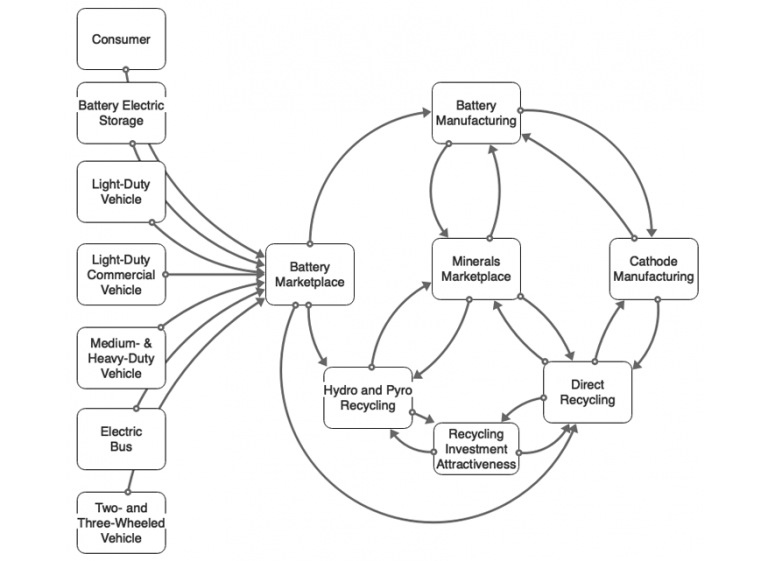

- Supply Chain and Systems Dynamics Modeling: The Lithium-ion Battery Resources Assessment (LIBRA) model uses system dynamics to project the buildout of the industries required for the rapidly-evolving global lithium-ion battery supply chain including manufacturing and recycling. Using the historical and projected demand for electric vehicles, stationary battery electric storage, and consumer electronics, LIBRA can track the movement of critical battery materials and components through the production, in-use, and end-of-life phases under varying market and technological development conditions. Outputs from the model’s logical feedback mechanisms can be used by industry, government decisionmakers, and researchers to evaluate how different future scenarios such as changes in EV adoption rates, battery lifetimes, the evolution of different chemistries, or variations in mineral prices can impact the flows of battery materials and development of these interconnected industries. An online interface for LIBRA allows users to conduct dynamic scenario analysis to learn more about how various levers impact the battery supply chain.

- Advanced Materials Characterization and Modeling: Use modeling and advanced characterization techniques (e.g., synchrotron X-ray methods and solid state NMR) to probe end-of-life materials that have been recycled and upcycled to study material quality and performance related to aging, impurities, and heterogeneities.

Learn more about the individual projects in these areas in our Quarterly Reports and Publications.